When we drive over smooth highways or walk across stable embankments, we rarely think about the "skeleton" hidden beneath the asphalt or soil. One of the most critical components in modern civil engineering is the Fiberglass Geogrid. But a question often arises among project managers, engineers, and curious observers:How does a simple bundle of glass fibers transform into a high-strength, weather-resistant mesh that can hold together massive infrastructure projects?

The answer lies in a highly sophisticated, continuous process known as the Production Line for Dipping of Fiberglass (Chemical Fiber) Geogrid. This process is a marvel of industrial engineering, ensuring that every square inch of the grid provides maximum reinforcement.

The Journey from Thread to Strength

The manufacturing of a geogrid isn't just about weaving; it’s about chemistry and precision tension. To understand the quality of the final product, we need to walk through the journey of the material as it moves through the facility.

1. The Starting Point: Precision Unwinding

The process begins with the raw material—knitted fiberglass. At the start of the Production Line, the knitted geogrid is placed into a specialized unwinding device. This isn't just a simple spool; it is a high-precision system.

Before any processing happens, technicians adjust the unwinding device to align perfectly with the center of the production line. If the alignment is off by even a few millimeters, the entire roll could skew, leading to uneven coating or structural weaknesses. This stage ensures that the "base" of our geogrid enters the system perfectly straight.

2. The Storage Rack: The Secret to Non-Stop Quality

One of the biggest challenges in industrial manufacturing is "downtime." When you have to stop a machine to load a new roll of material, the temperature in the ovens can fluctuate, and the chemical dip can settle unevenly.

To solve this, the geogrid is transported by a traction device into a storage rack. Think of this as a "buffer zone." It holds extra material so that when one roll ends and another is joined, the rest of the machines further down the line never have to stop. This continuous flow is vital for maintaining a consistent quality across thousands of meters of product.

3. The Heart of the Process: Dipping and Extrusion

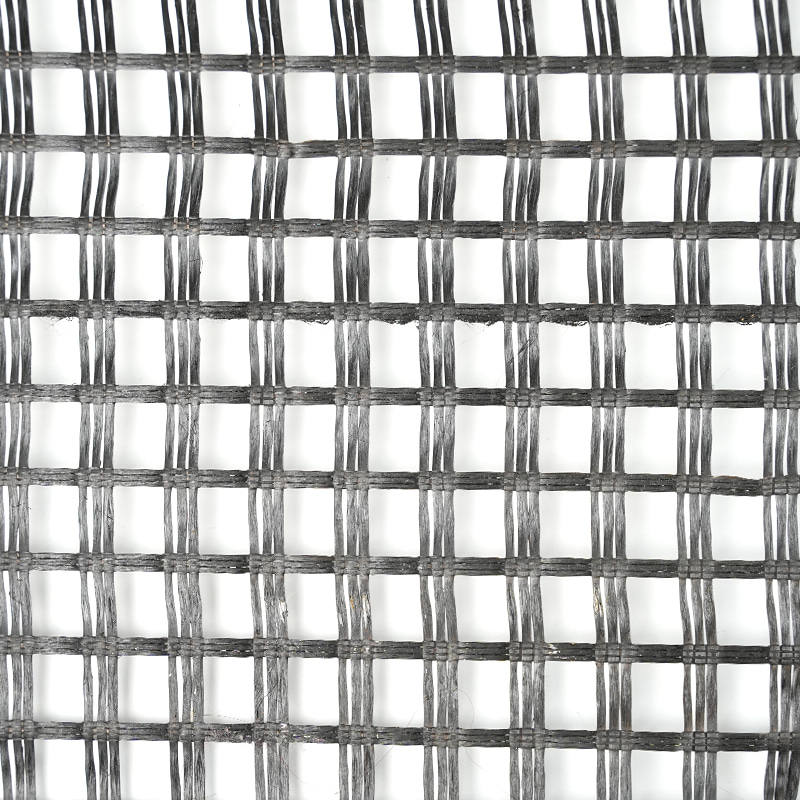

Fiberglass on its own is strong but brittle. It needs protection against moisture, UV rays, and the alkaline environment of soil and concrete. This is where the "Dipping" part of the Production Line comes in.

The grid enters a dipping device filled with a specialized polymer coating (often bitumen or PVC-based). The grid is submerged and then passed through an extrusion process. This ensures that every single fiber is thoroughly coated and that excess chemicals are squeezed out. This coating acts as the "armor" for the fiberglass, giving it the durability needed to last for decades underground.

The Science of Shape: Drying and Setting

Once the geogrid is coated, it is wet and flexible. To become the rigid, high-strength mesh used in construction, it must undergo a rigorous drying and "setting" process.

Pre-Drying: Setting the Coating

The wet grid first enters a pre-drying oven. This initial heat stage stabilizes the chemical coating so it doesn't drip or sag during the next, more intense phase. It’s a delicate balance—too much heat too fast could cause the coating to bubble; too little, and it won't set properly.

The Stenter Oven: Solving the "Arc" Problem

This is perhaps the most impressive part of the technology. After pre-drying, a post-tension conveyor pulls the grid into the stenter stereotypes oven.

In older manufacturing methods, the tension of being pulled through a machine would often cause the mesh to warp, creating what engineers call a "pre-arc" or "post-arc" effect. This means the horizontal and vertical lines of the grid would curve, significantly reducing its load-bearing capacity.

The modern Production Line solves this using independent clamps on both sides of the rail. These clamps grip the edges of the geogrid and pull it with programmed precision. Because they run independently, they can adjust the tension in real-time. The result? The longitude and latitude directions of the product remain in perfectly straight lines. When an engineer lays this grid down on a job site, they can trust that the geometry is perfect, ensuring the weight of the road is distributed exactly as designed.

Final Quality Control and Packaging

Even after the grid is dried and set, the process isn't quite over. It moves to a second storage rack at the end of the line.

Why a Second Storage Rack?

Just like the first rack, this one serves as a buffer. When the product reaches a specific, required length (for example, 50 or 100 meters), the system needs to cut the material and start a new roll. Without this storage rack, the entire oven system would have to stop every time a roll was finished. Instead, the rack accumulates the finished product for a few moments, allowing for an automatic cutoff and a seamless transition to the next roll.

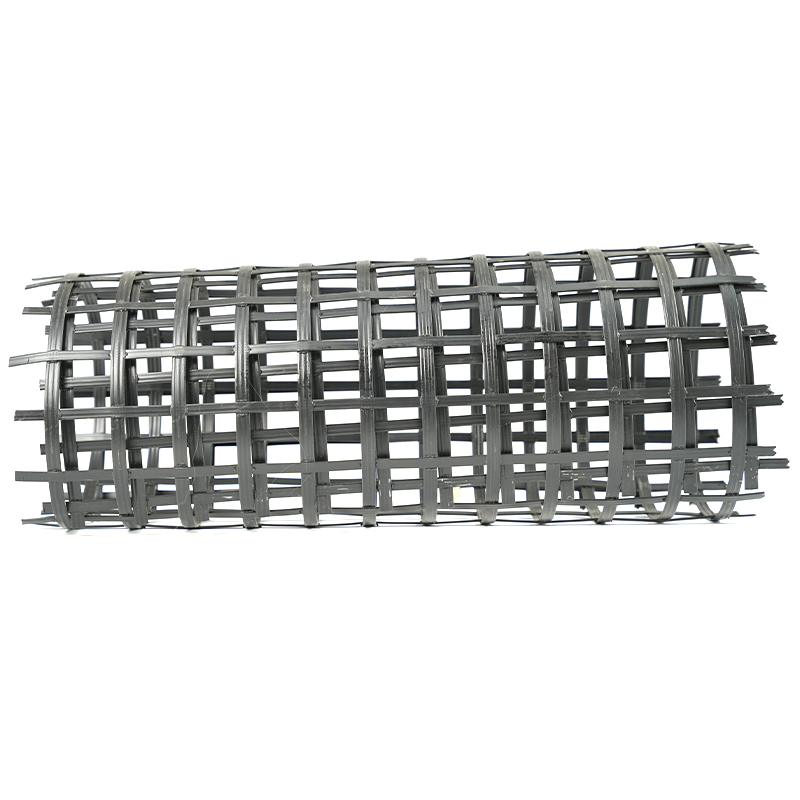

Rolling and Packing

Finally, the product is rolled tightly, labeled, and packed. This marks the completion of the dipping process. What started as a soft, white knitted fiber has emerged as a black (or coated), rigid, high-strength industrial component ready to reinforce the world’s infrastructure.

Frequently Asked Questions About Geogrid Production

To help you better understand why this specific production method matters, we’ve gathered some of the most common questions from industry professionals.

Q: Why is "continuous production" so important? A: In chemical dipping, consistency is king. If the line stops, the section of the grid currently in the oven might over-dry or become brittle. By using storage racks, the Production Line ensures that every meter of the geogrid experiences the exact same temperature and dipping time.

Q: Does the coating really matter that much? A: Absolutely. Fiberglass is incredibly strong in terms of tensile strength, but it can be damaged by abrasion from rocks or chemical reactions in the soil. The dipping process ensures the fibers are sealed away from these elements, preserving their strength for the long term.

Q: What happens if the grid isn't "straight"? A: If the longitude and latitude lines are arched (curved), the grid won't "catch" the soil or asphalt correctly. It’s like trying to use a rubber band that’s already stretched out. The independent rail system in the stenter oven ensures the grid is "true," providing maximum reinforcement the moment it is installed.

The Backbone of Modern Construction

The Production Line for Dipping of Fiberglass Geogrid represents the intersection of textile science and chemical engineering. By moving from a simple knit to a precisely coated, tensioned, and dried mesh, manufacturers are able to provide a product that saves lives by making roads safer and saves money by making infrastructure last longer.

Next time you see a construction crew laying down a dark mesh before the asphalt is poured, you’ll know the complex journey that material took—from the precision unwinding to the high-tech stenter ovens—all to ensure our world stays on solid ground.

English

English 中文简体

中文简体 русский

русский