In the world of modern civil engineering and infrastructure development, there are hidden heroes that keep our roads from cracking, our bridges from shifting, and our slopes from sliding. One of the most essential materials in this field is the uniaxial tensile geogrid. While it might look like a simple plastic mesh to the untrained eye, the process of creating it is a marvel of precision engineering.

Today, we are taking an in-depth look at the Production Line of Uniaxial Tensile Geogrid, exploring how raw plastic pellets are transformed into high-strength reinforcement materials that define the durability of 21st-century construction.

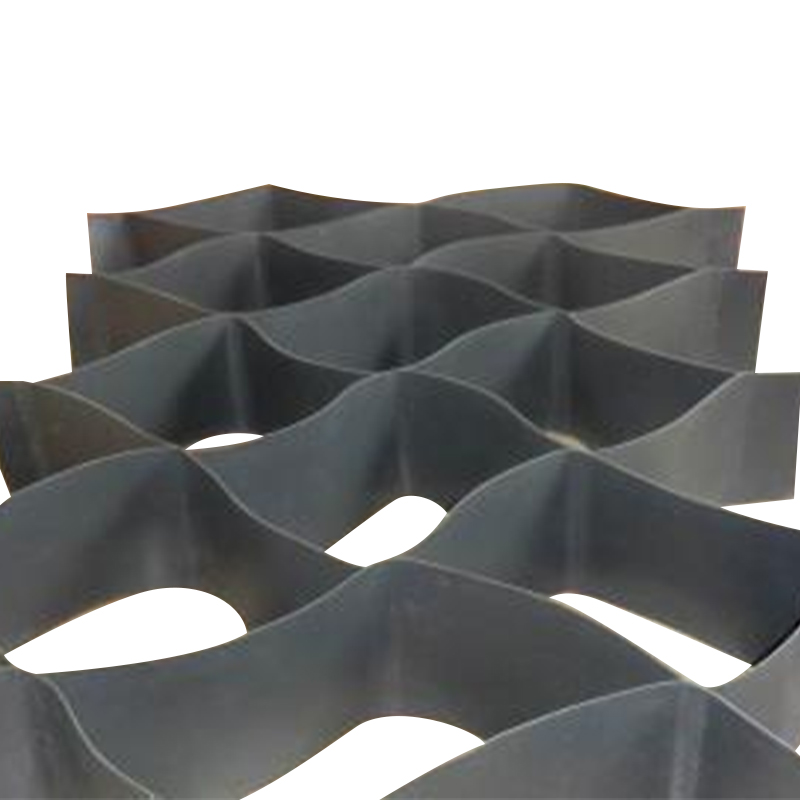

What is a Uniaxial Tensile Geogrid?

Before diving into the machinery, it is important to understand what we are making. A geogrid is a geosynthetic material used to reinforce soils and similar materials. A "uniaxial" grid is designed to be strong in one specific direction. This makes it perfect for retaining walls, steep slopes, and embankment reinforcements where the primary stress comes from a single angle.

To achieve this incredible strength, the plastic must undergo a rigorous manufacturing journey.

Melting and Extrusion

The journey begins at the extruder. The primary raw material—usually high-density polyethylene (HDPE) or polypropylene (PP)—starts as small, hard resin pellets. These pellets are fed into a large hopper.

Inside the extruder, a massive screw rotates, pushing the pellets through a heated barrel. The combination of friction and controlled electrical heating melts the plastic into a thick, molten liquid. The quality of the final geogrid depends heavily on this stage; the temperature must be perfect to ensure the polymer chains are ready for the transformation ahead.

From Liquid to Plate (The Moulding Phase)

Once the plastic is molten, it is forced through a plate mould. Think of this like a giant pasta machine. The mould shapes the liquid plastic into a continuous, flat sheet.

As the sheet emerges, it passes through a three-roller system. These rollers serve two purposes:

-

Consistency: They ensure the sheet is a uniform thickness across its entire width.

-

Surface Quality: They smoothen the material, preparing it for the structural changes it is about to undergo.

The Cooling and Finalization

Hot plastic is unstable. To "lock in" the dimensions of the sheet, it immediately enters a cooling water tank.

This step is known as "finalization." By rapidly lowering the temperature, the plastic transitions from a soft, pliable state to a solid, durable plate. This plate is the "blank canvas" from which the geogrid will be carved.

Precision Punching

This is where the material starts looking less like a sheet of plastic and more like a structural tool. The cooled plate is transported to a high-precision press for punching.

A series of industrial dies punch a calculated pattern of holes into the solid sheet. At this stage, the holes look like simple circles or ovals, and the material is still relatively thick and stiff. However, the spacing of these holes is critical; they determine exactly how the grid will stretch in the next phase.

Step 5: The Magic of Reheating

You might wonder why we cool the plastic only to heat it up again. The answer lies in molecular science. To create a uniaxial tensile geogrid, we need to align the polymer chains to give them "tensile strength"—the ability to resist being pulled apart.

The punched plate is moved by a conveyor belt into a long, specialized oven. The temperature here is carefully regulated to soften the plastic without melting it. This makes the material "elastic" enough to be manipulated without snapping.

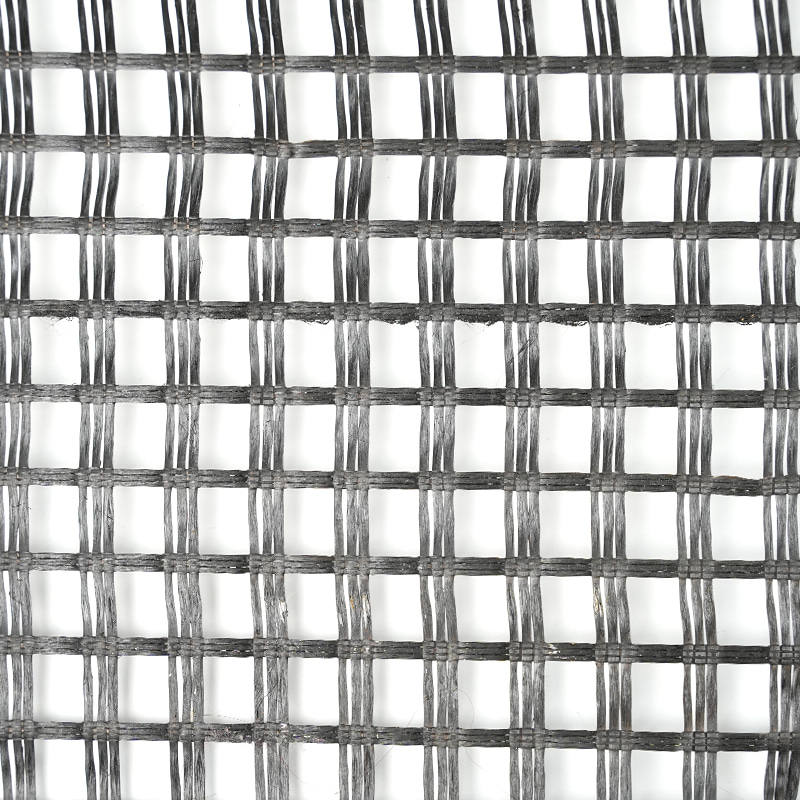

The Stretching (Orientation) Phase

This is the most critical part of the Production Line of Uniaxial Tensile Geogrid. Once the heated, punched plate leaves the oven, it enters the stretching devices.

In uniaxial production, the machine pulls the sheet in one longitudinal direction. As the material is stretched, the small holes that were punched earlier begin to elongate, turning into long, slender rectangles or "ribs."

Why Stretching Matters

When the plastic is pulled, the random microscopic polymer chains are forced to align in a straight line. This process, called molecular orientation, increases the strength of the plastic exponentially. What started as a flexible sheet becomes a high-strength rib that can support tons of soil pressure.

Completion and Quality Control

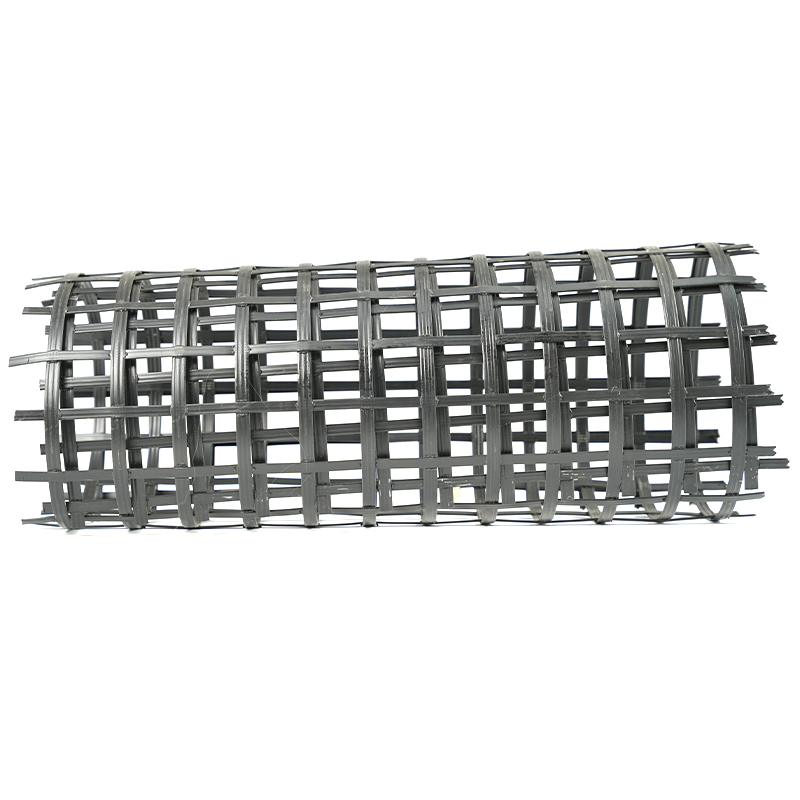

Once the stretching is complete, the uniaxial tensile geogrid has reached its final form. It is now a high-performance reinforcement mesh. But the job isn't done yet.

The finished product undergoes several final steps:

-

Measurement: Sensors check the width, thickness, and rib strength to ensure they meet international engineering standards.

-

Rolling: The long continuous sheet of geogrid is wound onto large industrial cores.

-

Packing: The rolls are wrapped in protective material to prevent UV damage or physical wear during transport.

Why This Process is a Game Changer for Construction

The Production Line of Uniaxial Tensile Geogrid represents a shift toward more sustainable and efficient building. By using these grids, engineers can:

-

Reduce Material Waste: Instead of using massive amounts of concrete or steel, they can use geogrids to stabilize the earth itself.

-

Increase Longevity: Roads built with geogrid reinforcement last significantly longer and are less prone to "potholes" or sinking.

-

Environmentally Friendly: Many of the raw materials used in the extrusion process can be sourced from recycled plastics, reducing the carbon footprint of major infrastructure projects.

The Future of the Production Line

As technology advances, these production lines are becoming more automated. Modern lines use AI-driven thermal imaging to monitor the oven temperature and laser-guided punching systems to ensure there isn't a single millimeter of error.

The demand for these materials is skyrocketing. As cities expand and the need for more resilient transport networks grows, the Production Line of Uniaxial Tensile Geogrid will remain at the heart of the manufacturing world, turning simple plastic into the backbone of our modern world.

From the first pellet of resin in the extruder to the final roll loaded onto a truck, every step in this process is a testament to the power of industrial design. It is a seamless flow of heating, cooling, punching, and stretching—a perfect dance of machine and material.

The next time you drive through a mountain pass or walk along a reinforced riverbank, remember the complex journey of the geogrid beneath your feet. It started in a high-heat extruder, was precisely punched by a heavy press, and was stretched to its limit to ensure your safety and the stability of the ground.

The Production Line of Uniaxial Tensile Geogrid is more than just a series of machines; it is the birthplace of modern structural integrity.

Content

- 1 What is a Uniaxial Tensile Geogrid?

- 2 Melting and Extrusion

- 3 From Liquid to Plate (The Moulding Phase)

- 4 The Cooling and Finalization

- 5 Precision Punching

- 6 Step 5: The Magic of Reheating

- 7 The Stretching (Orientation) Phase

- 8 Completion and Quality Control

- 9 Why This Process is a Game Changer for Construction

- 10 The Future of the Production Line

English

English 中文简体

中文简体 русский

русский